Sawdust Sustainability – From Waste to Resource

Here at the Doherty Group our sawdust comes to us after being part of a different process. When wood is used in the manufacturing process, for example the construction of timber frames, the natural and abundant by-product of this is always sawdust. Within these industries and many others, sawdust is considered a “waste” product. However, as you may well know, sawdust has plenty of potential to not only be a useful resource, but a surprisingly sustainable one too.

Where does it come from?

While in many cases sawdust is a sustainable alternative to other resources and materials, it can’t be taken for granted that this is always the case. Unfortunately, there are still sources of wood which don’t meet the sustainability requirements that they really ought to. Thankfully this is less and less common and initiatives like those by the Forestry Stewardship Council have made huge strides to eliminating unethical and unsustainable deforestation, especially here in the UK and Ireland.

At the Doherty Group we aren’t in the business of cutting down trees and turning them into piles of sawdust. We don’t see that as a sustainable way to do business, and frankly you shouldn’t either! The reality of using wood as a manufacturing and building material is that there will be sawdust left over… and that’s where we come in! Turning this by-product into a useful and potentially environmentally beneficial resource is what we’ve been doing for over 30 years.

But isn’t a waste product going to be poorer quality?

The short answer: Absolutely not.

See, we are rather picky with our suppliers – we know that all of them meet stringent sustainability and quality parameters which mean the sawdust we process isn’t just environmentally friendly, its also the good stuff. No nasty mixes of MDF or treated wood with glues, resins, bits of plastic or any other junk – just 100% wood – and most of it, pine.

Ok, but what about the lifecycle of the sawdust, where does it end up?

Here’s the good bit – it can end up a multitude of places, but being a fully biodegradable product, it’s uniquely positioned that wherever it ends up it’s likely to either be gone before too long, or even potentially helpful during the decomposition process.

Sawdust is most commonly used in 3 key ways – animal bedding, composting and biomass fuel. Sometimes it can be used for more than one and more often than not using a wood alternative supports the circular economy.

If used as animal bedding.

Sawdust and shavings are most commonly used in stables, dairy systems and poultry houses.

Within horse stables, used bedding can end up as a nutrient rich compost combining the nutrients found in manure with the carbon sequestering benefits and mulching properties of sawdust.

Dairy cattle bedding most commonly ends up in slurry pits and used to fertilise fields directly. Sawdust works well within slurry systems as it doesn’t cause blockages and actually adds to the nutrient richness of each slurry application. Similar to composting, this creates a sustainable cycle with wood eventually being re-integrated into the local eco-system.

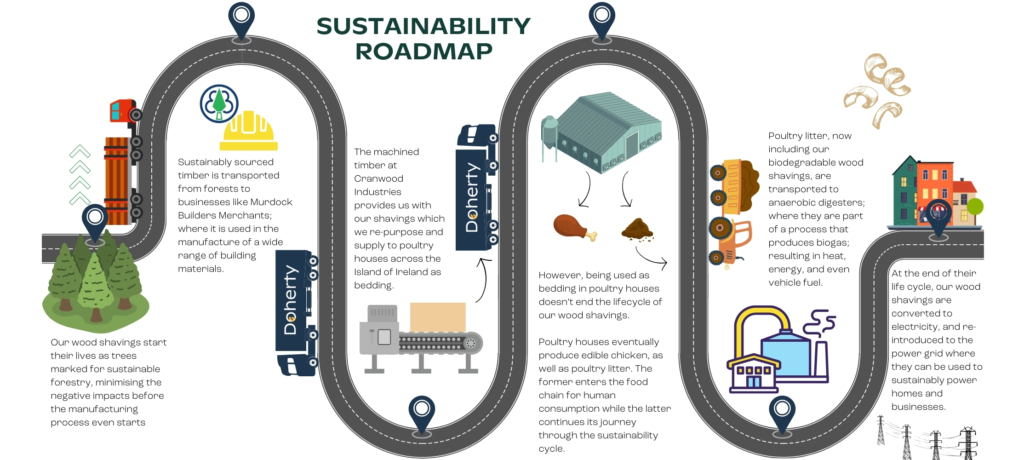

Here’s what the lifecycle of our poultry shavings could look like:

If used as an alternative fuel source.

The other way in which wood waste is often used is as a biomass fuel alternative. We aren’t here to pull the wool over anyone’s eyes and acknowledge that there are both benefits and drawbacks to this – however, if sourced from sustainable partners and burned efficiently, wood is a much better alternative to fossil fuels. Fortunately, modern pellet stoves and biomass systems are extremely efficient and the renewable nature of wood greatly increases the carbon neutrality of the product when compared to alternatives.

To summarise.

If you’re looking for a quality, reliable alternative to other forms of animal bedding and biomass fuel, or you’re simply looking for a guarantee that the company you buy from source from ethical and sustainable suppliers, we have you covered.

Sawdust and shavings can be so much more than a by-product of other processes, and with the correct application can even add back to the local ecosystem, reducing your carbon footprint and ever so slightly contributing to a greener countryside.

Contact us to find out more!